Below is a stress strain graph that reviews the properties of steel in detail.

Stress strain curve of ceramic vs metal.

It is difficult to shape these materials into the proper test structure difficult to grab the brittle material without breaking it and it is difficult to align the test samples to avoid bending stresses.

If the force is small enough the ratio of the stress and strain will remain proportional.

The first two are strength parameters.

Elastomers are the ones that strains more w a lower stress.

Tensile tests of brittle ceramics are usually not performed.

The general shape of the engineering stress strain curve fig.

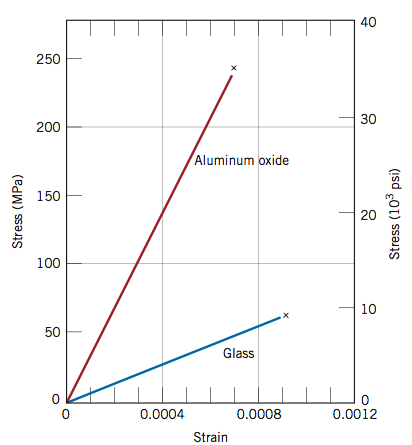

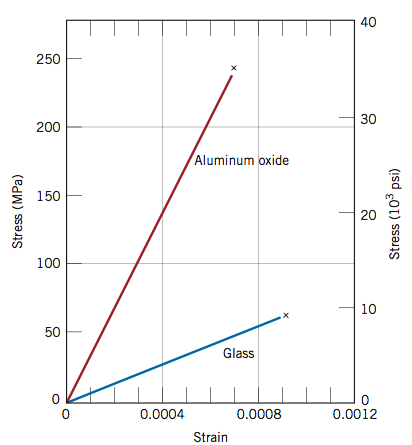

Stress strain curves for two brittle materials.

The parameters which are used to describe the stress strain curve of a metal are the tensile strength yield strength or yield point percent elongation and reduction of area.

The last two indicate ductility.

In this booster you will learn about design stress strain curve of concrete and steel as per is 456 2000.

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

In this the stress is plotted on the y axis and its corresponding strain on the x axis.

If tensile force is applied to a steel bar it will have some elongation.

After the point d the material due to strain hardening again starts taking load and the curve rises as seen in the.

We used these curve for limit state method.

Stress strain curve is the plot of stress and strain of a material or metal on the graph.

Also learn about the stress strain graph for various materials like brittle ela.

While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics.

When steel is curved it is important to keep the stress strain curve ratio for mild steel in mind.

1 requires further explanation.

Lean how a wire behaves under increasing load using the stress strain graph.

After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram.

With a very short elastic region but highly capable of supporting huge stresses.

The stress strain curve in this part of the graph is almost horizontal which implies that there is an appreciable increase in strain for a negligible increase in stress.

Yielding starts at c and ends at d.

2 stress strain curve for ceramics.